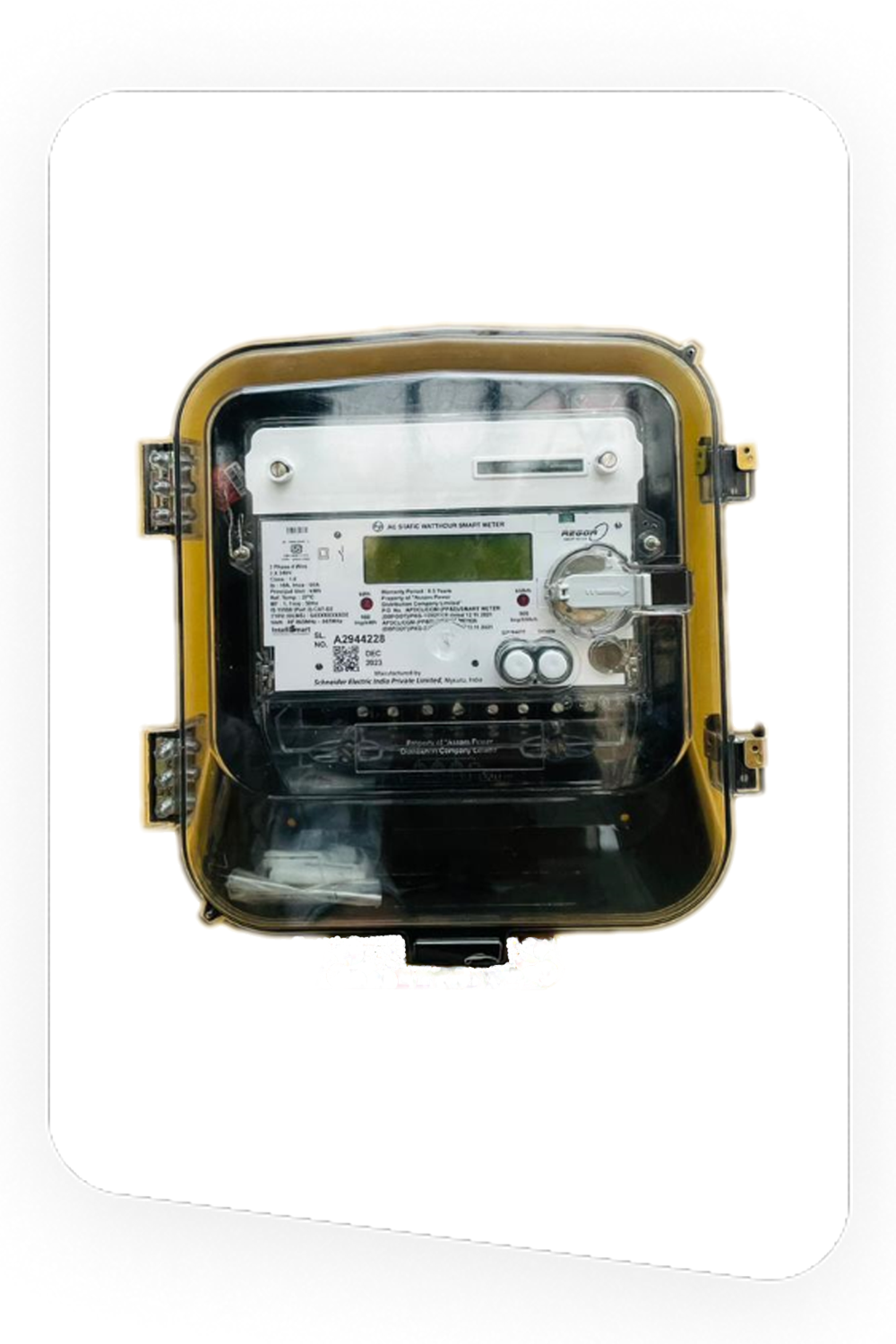

Smart Energy Meters

DIRECT CONNECTED, WHOLE CURRENT, A.C. SINGLE PHASE, TWO WIRE SMART ENERGY METER OF ACCURACY CLASS 1.0 WITH BI-DIRECTIONAL COMMUNICATION FACILITY SUITABLE FOR ADVANCED METERING INFRASTRUCTURE (AMI), DESIGNED TO MEET IS:16444.

Features

- Measured parameters – V, A, KWH, kVArh

- Multi-rate calculations

- Built-in clock

- Event logging

- Load profiling

- Differential current measurement

- IP 54 protection level

- Built-in Relay

- Standard data model & Open protocols

- Optical ports

- Replaceable battery

- Meter cover open, Terminal block cover open & Communication module cover open sensors

- Magnetic field sensor

- Magnetic protection shield

- WAN or NAN communication module

- Built-in communication interface

- Pre-payment programmable

Consumer indexing

It is the process of systematically collecting and recording

1) General information such as Division code, Subdivision code, Substation, Feeder, Distribution transformer, Pole number, LT-CT ratio of the Distribution transformer, feeder meter details etc.,

2) Consumer information such as Name, Permanent address, Correct address, Landmark, Mobile number, Email ID, Occupant name, Occupant mobile number etc.,

3) Existing meter information such as Meter makes, Meter number, kVAh/kWh reading, type, MF, meter box, Seal status, Pole type (LT/HT), location (inside/outside), Meter photo, status of service cable, Type of service cable, presence of joints in the service cable, Number of meters connected to this pole, Any other remarks.

4) GIS information such as Latitude, Longitude, survey date

5) Communication type such as RF / GPRS

Meter Installation

It is the process of installation and commissioning of meters as per correct data collected during consumer indexing and further collecting and recording the following data

- Newly installed smart meter details such as Meter number, Reading kVah/kWh, Type, Manufacturer detail, MD, Terminal cover seal number, Body cover seal number, Error code if displayed any, Installation date, Meter outer box seal number1 and seal number2.

- Location details such as Longitude and Latitude details

- Images and consumer acknowledgment such as old meter photo, New meter photo, Meter Replacement Note photo, New meter bar code data.

Operation and Maintenance

Immediately after one month of installation & commissioning, the Operation & Maintenance phase starts. This includes

1) Doing field verification and generate report which include

- Meter installation done as per approved Customer Indexing data

- Data collected during meter installation is correct or not

- Using AMISP suggested Apps. To test the communication network signal strength

- Error codes if any displayed by the meter

- Whether meter is installed inside metallic enclosure

- Whether meter is installed in the basement

- Any joints observed in the service cable

- Any loose cable connection observed

- Sealing properly done

- Availability of terminal box

- Availability of communication module box

- Availability of DISCOM seal

- Any physical meter tamper observed

- Availability of label on the meter showing old meter number, reading, MI date, account number, agency name.

- Any other observations.

2) Attending to the tickets raised by the AMISP / DISCOM

3) Servicing and closing the calls within the agreed Service Level Agreement (SLA)

4) Doing periodic field inspection and submitting the same to AMISP / DISCOM

5) Visiting consumer location and work with AMISP and DISCOM in trouble shooting meter related issues

Specification

| Parameters | Specification |

| Current Rating | 5/30A or 10/60A |

| Starting current | As per IS 16444 |

| Accuracy | Class 1.0 |

| Limits of error | As per IS 16444 |

| Operating temperature range | As per IS 16444 |

| Operating Humidity | As per IS 16444 |

| Frequency | As per IS 16444 |

| Influence quantities | As per IS 16444 |

| Power consumption of meter | As per IS 16444 |

| Current and Voltage circuit | As per IS 16444 |

| Running at No Load | As per IS 16444 |

| Meter display | As per IS 16444 |

| Parameters to be measured | As per IS 16444 / IS 15959 Part-2 |

| Maximum Demand reset | As per IS 15959 Part-2 |

| Time of use registers | As per IS 15959 Part-2 |

| Power Quality information | As per IS 15959 Part-2 |

| LED, LCD indicators | As per IS 16444 |

| Tamper / Event recordings | As per IS 16444 |

| Remote Firmware upgrade | As per IS 15959 Part-2 |

| Load control | As per IS 16444 |